YH-5000SE BEHIND THE SCENES

MESSAGE FROM THE ENGINEERS

THE INSPIRATION FOR YH-5000SE

When developing the YH-5000SE, we pursued the ultimate musical experience of immersing yourself completely in music. To achieve this, we insisted on using only the finest components and design for all aspects of sound, while also considering wearability and build quality.

With these extraordinary headphones, we believe you'll fall in love with your favorite music all over again while hearing nuances, colors and details you may not have noticed before.

RYO HADANO

Acoustic Design

Our ORTHODYNAMIC™ driver was born in the ‘70s. Six years had passed since the earliest days of development when I studied drawings left in the company’s old drawers, to the time when the headphones took shape in their present form after many prototypes and trials. These headphones release details trapped in the sound source while balancing the density of sound, allowing the listener to focus on the music. Ultimately, this was our target objective for the YH-5000SE. For this reason, we worked hard on all components and structures, including the driver unit. When the listener can hear the attention to detail in recordings made by great artists and engineers, the music will remain deeply in their hearts with more realism, resulting in a superlative experience.

CHIKARA KOBAYASHI

Mechanical and Housing Design

With the YH-5000SE, we used carefully selected materials, from the structural members to the surface materials and finishes. We adhered to the principle “materials should be chosen for a reason” to achieve the sound quality, wearability, and design we initially set out to deliver. The YH-5000SE headphones use delicate materials that are difficult to handle and materials that are not often found in audio products. We created them with the utmost care, from material selection to the manufacturing process, so as not to compromise their ideal acoustic properties and aesthetic appearance. And the letters “MADE IN JAPAN” engraved on the body are also a testament to the level of quality that should satisfy meticulous audiophiles.

YASUAKI TAKANO

Affective Evaluation

“What does it mean for headphones to be comfortable?”

“How do listeners want headphones to feel when wearing them?”

For the YH-5000SE, we began by taking an in-depth look at the essence of these questions. Within our R&D department, there is a team dedicated to affective evaluation, which is working to scientifically quantify human sensitivity and perception in the sound and music domain. For this model, in cooperation with that team, we prepared dozens of prototypes with various changes to the lateral pressure of the headphones, earpad surfaces, and the cushioning material. We then conducted repeated tests to find the most suitable combination for long-term listening. Specifically, we sought to achieve the ideal wearing comfort by meticulously measuring whether the headphones would touch the top of the head and the side of the face evenly, and would apply minimum pressure, even for people with irregular-shaped heads. We did this using a surface pressure measuring instrument, and by evaluating sensitivity over long periods of use. We hope you will immerse yourself in the world of music with these headphones, and that they will be so comfortable you will forget you are even wearing them.

Yamaha Flagship headphones YH-5000SE | MESSAGE FROM THE ENGINEERS

ALL ABOUT ORTHODYNAMIC™

— PURSUING WHAT IS TRUE FOR ALL TIMES —

Our first-generation Orthodynamic™ driver was born in 1976. “ORTHO” in Greek means “correct” and “straight,” and our first-generation Orthodynamic™ driver was based on the idea of correctly driving the diaphragm for greater accuracy in reproducing the sound. Our concept remains unchanged, and has further evolved into True Sound.

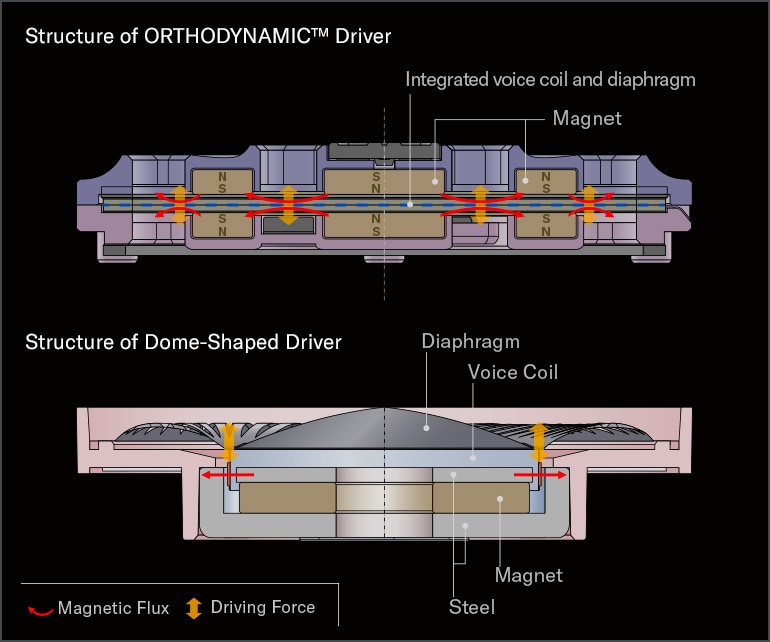

WHAT IS AN ORTHODYNAMIC™ DRIVER?

Headphone drivers come in various types. The most common is a dynamic driver, which drives a voice coil bonded to a dome-shaped diaphragm by sending electrical signals in combination with permanent magnets. There are also planar magnetic field drivers which use a thin-film diaphragm integrated with a voice coil sandwiched between permanent magnets to deliver drive. Since planar magnetic drivers drive the entire diaphragm, they are more responsive than dynamic drivers and offer excellent high-frequency performance and low distortion. However, due to their structure, advanced technology is required for development and manufacturing. In addition, even among planar magnetic drivers, different manufacturers have different solutions for the diaphragm and voice coil.

Our Orthodynamic™ driver, however, adopts a true circular shape for the diaphragm, and the coil pattern also has a circular spiral shape. With this concentric circular corrugation, the operation of the diaphragm in the piston motion area is smooth, giving the headphones excellent responsiveness and rich dynamic sound.

HISTORY OF ORTHODYNAMIC™ TECHNOLOGY

Many manufacturers tried to develop planar magnetic drivers in the 1970s, but due to their complex structure and difficulty in manufacturing, only Yamaha and a few other companies were successful. Our first Orthodynamic™ driver was manufactured by photoetching a spiral-shaped voice coil on a thin film of polyester, and the very complex structure of five divided spiral patterns arranged concentrically, alternating their winding directions, made it extremely difficult to develop and manufacture.

We overcame these challenges and released the HP-1, our first-generation Orthodynamic™ Stereo Headphones. The HP-1 was acclaimed for its excellent sound quality, and the simple and practical design by Italian industrial designer Mario Bellini was also well received.

THE EVOLUTION OF THE ORTHODYNAMIC™ DRIVER

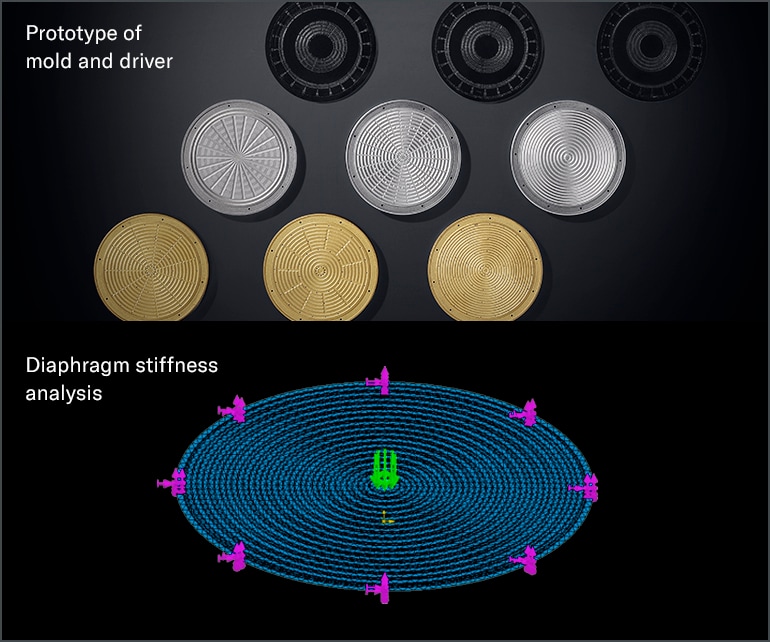

When a project to create an unprecedented pair of headphones was launched within Yamaha, the engineers were inspired by the Yamaha headphones of the 1970s. They became interested in the Orthodynamic™ driver as they sought out ways to deliver an excellent quality attack that matches modern music sources, including high-resolution sound sources. Although it was extremely difficult to design a diaphragm that could deliver high accuracy, roughly a thousand different prototypes were made before they finally arrived at the current design. They insisted on choosing the finest materials and components and came up with the manufacturing method. The engineers worked to perfect the form and structure by repeating many processes of measurement, analysis, and improvement. The new Orthodynamic™ driver features a larger opening than the previous model to increase the transmittance of sound from the diaphragm. In addition, the resonance frequency is lowered by eliminating the center fixation on the diaphragm to deliver a full expression of low-range frequencies and a tremendously dynamic sound. The engineers also reviewed the damping method and changed the previous felt damping to a micropore damper, making it possible to deliver an agile attack and minimize losses in the mid-to-high range.

Everything we do is aimed at delivering True Sound. This includes our new Orthodynamic™ driver which took over six years to develop. We invite you to experience this new True Sound that we hope will inspire you and bring you the highest level of listening enjoyment.